Modern Metal Works Techniques That Old-School Craftsmen Never Knew About

Metal works have an incredible history dating back to 8,700 BCE when early copper mining began. The techniques used today would amaze our ancient ancestors. Ancient metalworking started with simple copper tools, and gold artifacts emerged later in 4450 BCE Bulgaria. The craft has come a long way since then.

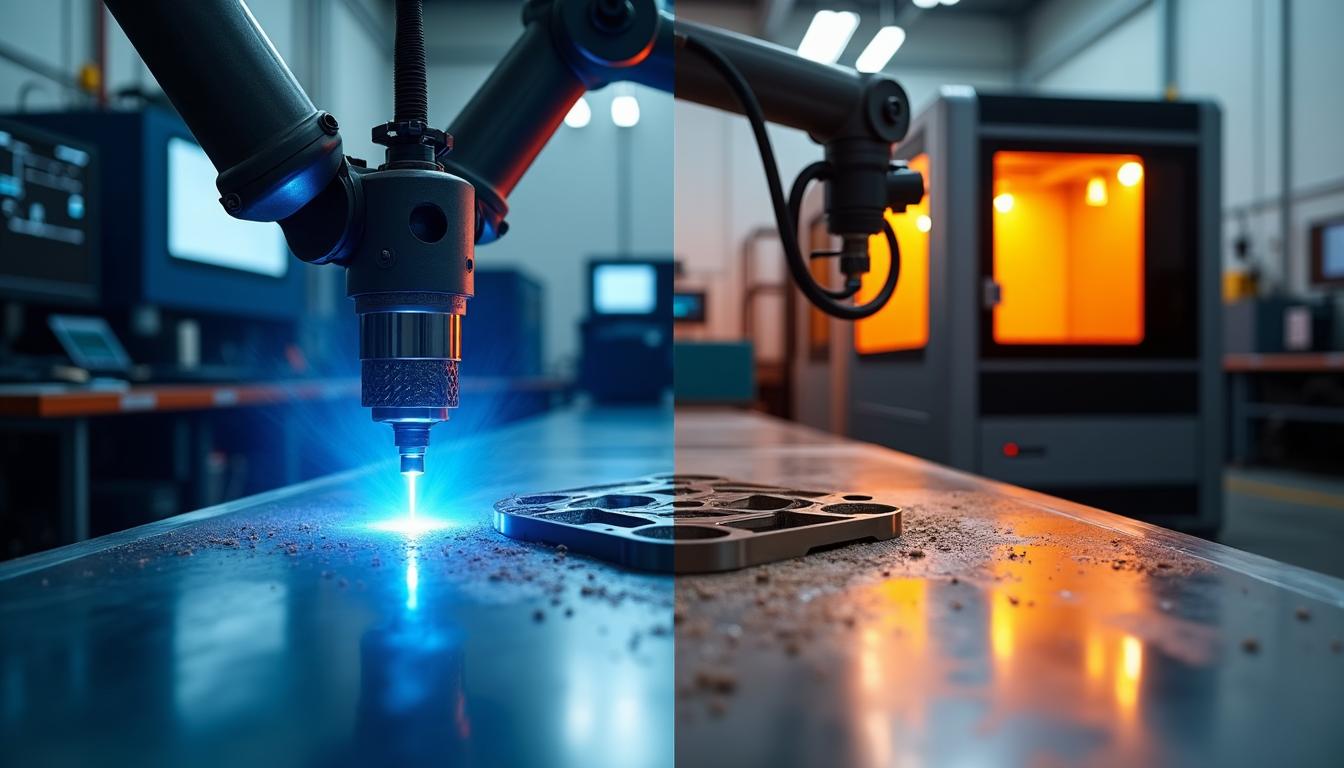

Modern metalworking represents a dramatic shift from traditional methods. Workshops now function as precision manufacturing centers thanks to Computer Numerical Control (CNC) technology, laser cutting, and water jet cutting. These advanced processes have substantially improved production speed and quality compared to older techniques. Modern approaches continue to shape metalworking’s future while preserving the fundamental principles that craftsmen have followed for thousands of years.

Digital Revolution in Metal Works

The metalworking industry has entered a new era of state-of-the-art technology. Precision and efficiency now define modern manufacturing processes. Computer-Aided Design (CAD) software has become the life-blood of this transformation and helps designers create highly detailed 2D and 3D models with unmatched accuracy.

Computer-Aided Design and Manufacturing

CAD systems now provide complete project management features that improve the production workflow. These systems generate precise measurements and calculations at the start to minimize waste and ensure structural integrity. The integration with Computer-Aided Manufacturing (CAM) creates a natural connection between design and production phases. Digital designs automatically convert into machine instructions.

3D Metal Printing Technologies

Metal 3D printing brings remarkable capabilities to manufacturing complex components. This technology excels at creating:

- Prototypes and final-use parts

- Lightweight components for aerospace applications

- Combined multi-part assemblies

BMW has accepted this technology and set up a fully automated additive manufacturing line to produce automotive components in series.

Laser Cutting Precision

Laser cutting technology has redefined precision in metal fabrication. The market for these machines will reach DKK 40.56 billion by 2022. Modern laser systems blend with CAD/CAM software to optimize cutting paths and control cutting parameters precisely. The technology cuts steel, aluminum, brass, and copper of all types with exceptional accuracy.

Advanced Automation Systems

Automation systems have changed metal fabrication processes at their core. They bring new levels of precision and efficiency to the industry. Today’s automated solutions handle complex tasks with great accuracy and consistency.

Robotic Welding Solutions

Robotic welding systems achieve productivity rates up to 85%, which far exceeds the 20% efficiency of skilled human welders. These systems work well with automotive components, railway equipment, and precision manufacturing. Today’s welding robots blend sophisticated vision systems with precise tools that enable three-dimensional welding for specific manufacturing needs.

Smart Metal Bending Technologies

Sheet metal forming has taken a leap forward with advanced bending automation. The ByCell Bend Smart system delivers press capacities from 50 to 300 tons and handles payloads up to 130 kilograms. These systems come with smart layouts that work with bulky parts and automatic gripper changing mechanisms that boost overall productivity.

Automated Quality Control Systems

Quality control automation has grown beyond simple inspection tasks. Modern systems now include:

- Vision-guided robots for dimensional validation

- Sophisticated sensors for live monitoring

- Advanced algorithms for defect detection

- Predictive maintenance capabilities

These automated inspection systems excel at detecting variations that human eyes might miss. They work around the clock without fatigue and maintain consistent quality standards throughout production runs. Companies that use automated quality control see significant drops in material waste and rework needs.

Automated systems help solve labor shortage issues effectively. This is crucial since more than 80% of production failures and defects usually come from human error. The addition of these advanced systems optimizes production efficiency and delivers consistent quality in metal fabrication processes.

Sustainable Metal Working Practices

Metal manufacturing’s effect on the environment just needs immediate attention. The industry generates 40% of all industrial greenhouse gas emissions and consumes 10% of global energy. Manufacturers now embrace environmentally responsible practices to reduce their ecological footprint while maintaining production quality.

Eco-friendly Metal Processing

Environmentally responsible metal processing starts with smart material selection. Electric arc furnaces are nowhere near as energy-hungry as traditional blast furnaces. These furnaces are the life-blood of eco-friendly manufacturing. The cost of crude steel production has dropped 60% since 1960. Advanced water treatment systems now filter and purify manufacturing water to protect local ecosystems from harmful contaminants.

Waste Reduction Techniques

Modern metal fabrication pioneers waste reduction through material efficiency. Several key improvements have emerged through modern techniques:

- Laser cutting and CNC machining achieve higher precision to optimize material usage

- Scrap metal processing enables better sorting and cleaning for high-quality material reuse

- Closed-loop water systems minimize fresh water requirements and reduce wastewater output

Predictive maintenance systems use sensors to monitor machine performance. This allows manufacturers to fix issues before breakdowns happen and reduces material waste.

Energy-Efficient Equipment

Energy costs make up 20% to 40% of metal production’s manufacturing expenses. Heat recovery systems capture and reuse waste heat from industrial processes to boost efficiency. The International Renewable Energy Agency reports that changing to scrap-based steel can cut energy consumption by up to 60%. Modern equipment uses sophisticated sensors and AI technology to optimize energy use. This ensures machines consume only what they just need.

Modern Metal Finishing Techniques

Metal finishing techniques have moved past traditional methods. New sophisticated surface treatments now improve both functionality and durability. These advances show a major change in how manufacturers prepare metals for different applications.

Plasma Surface Treatment

Plasma treatment emerges as an innovative approach to metal surface preparation. This process creates electron bombardment that breaks surface chemical bonds and changes the material’s properties. The treatment forms amorphous, adherent layers through non-electrolytic chemical reactions between solutions and metal surfaces. The process can also raise surface energy levels, which makes metals more receptive to coatings and prints.

Nano-coating Applications

Without doubt, nano-coating technology has transformed metal protection. Modern nano-coatings measure between 1 and 100 nanometers in thickness, while a human hair spans 80,000 to 100,000 nanometers. These microscopic coatings deliver remarkable benefits:

- Boosted durability without compromising other qualities

- Improved electrical conductivity

- Anti-microbial properties

- Superior resistance to chemical, heat, and moisture corrosion

Advanced Corrosion Protection

Modern corrosion protection works alongside traditional methods and uses intelligent anti-corrosive coatings with micro/nano carriers. These advanced systems can increase steel’s electrochemical impedance values by 2-3 orders of magnitude compared to standard coatings. All the same, optimal protection needs careful analysis of carrier design, coating matrix compatibility and environmental stability.

Corrosion affects between 3% to 6% of a country’s GNP, with global costs reaching USD 2.5 trillion annually. These advanced finishing techniques give manufacturers powerful tools to curb this ongoing challenge while boosting product performance and longevity.

Conclusion

Metal fabrication has come a long way from its ancient roots. Modern workshops have become advanced manufacturing centers. Thanks to computer-aided design and 3D printing, metalworkers now craft intricate components with amazing precision. Robots and automated quality checks have reduced human errors by 80% while maintaining consistent quality.

The industry now focuses heavily on being eco-friendly. Electric arc furnaces and closed-loop systems have reduced environmental effects by a lot. New finishing methods, particularly nano-coating, protect against corrosion better than ever – a problem that costs industries $2.5 trillion each year.

These improvements go beyond just better technology. They show how dedicated we are to precision, efficiency, and protecting the environment in metal fabrication. Our team uses advanced solutions for everything from complex components to specialized finishing work. You can reach out through our contact page to ask about your metalworking needs and learn how modern techniques can improve your projects.

The future of metalworking keeps challenging what’s possible. We build on thousands of years of craftsmanship while exploring new innovations. This blend of time-tested expertise and modern techniques will keep shaping our future in exciting ways.

FAQs

Q1. What are some modern metal fabrication techniques that weren't available to traditional craftsmen?

Modern techniques include computer-aided design (CAD), 3D metal printing, laser cutting, robotic welding, and automated quality control systems. These technologies offer unprecedented precision, efficiency, and capabilities in metal fabrication.

Q2. How has sustainability been incorporated into modern metalworking practices?

Sustainable metalworking now includes eco-friendly processing methods, waste reduction techniques, and energy-efficient equipment. Examples include electric arc furnaces, closed-loop water systems, and the integration of renewable energy sources in manufacturing processes.

Q3. What advancements have been made in metal finishing techniques?

Recent advancements include plasma surface treatment, nano-coating applications, and advanced corrosion protection systems. These techniques offer superior durability, improved functionality, and enhanced resistance to environmental factors compared to traditional methods.

Q4. How has automation impacted the metalworking industry?

Automation has significantly increased productivity and precision in metalworking. Robotic welding solutions, smart metal bending technologies, and automated quality control systems have reduced human error, improved consistency, and allowed for more complex manufacturing processes.

Leave a Reply