Our Company

The production facilities of our new plant occupy 15,000 square meters, which allows us to provide almost all types of subcontractor services in the fields of mechanical engineering and metalworking. We work with ferrous, stainless steel and aluminum, both at the procurement and welding stages, and for processing via CNC machines.

Our company provides Product Liability Insurance to support most important supply chain processes.

With years of experience in metal parts manufacturing, our trained professionals are ready to help you implement your production ideas into life and fulfill your business needs.

Following the highest quality standards of production, we stay in line with all the necessary production certificates (EN 1090-2, ISO 9001:2015, ISO 3834-2) and quality management systems (such as Monitor ERP).

See our international standards certification:

Our Services

Freen offers various range of custom metal processing services, including production of engine units details. We can become your trusted supplier for procurement services on EU market and partner for manufacturing expansion in DACH – CEE regions. We accept mass orders only.

01.

Laser Cut Services

02.

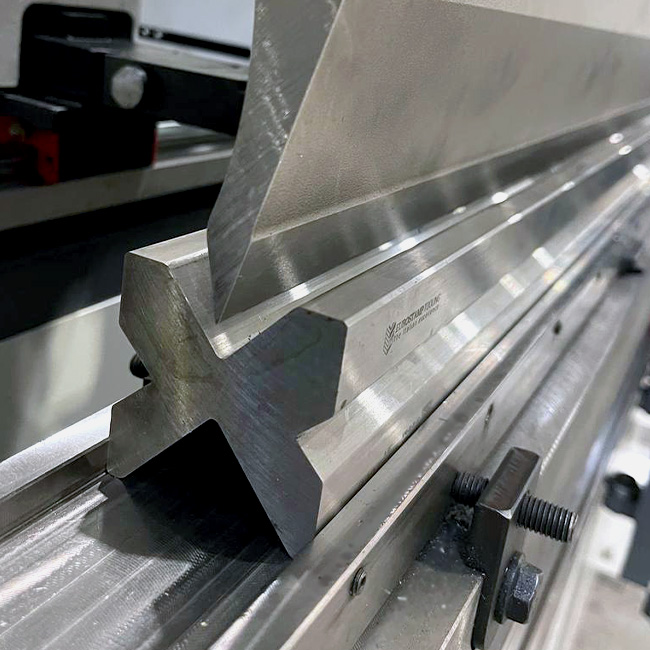

Sheet Metal Bending Services

03.

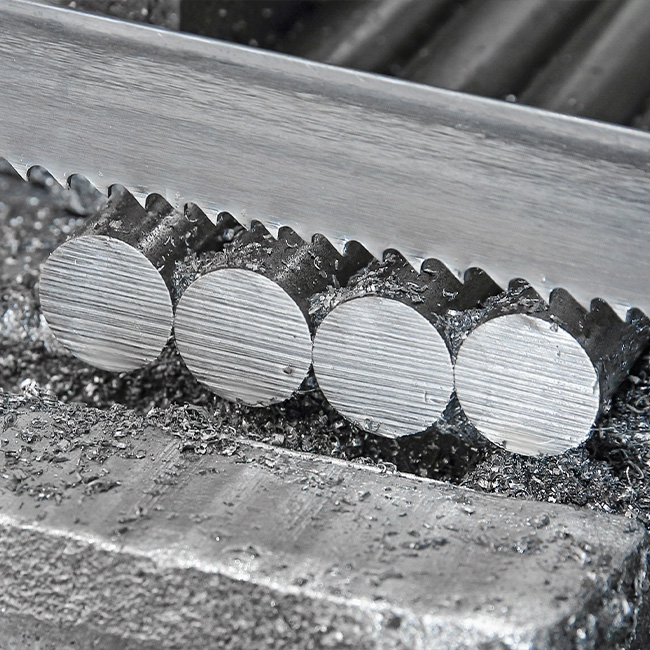

Metal Sawing Services

04.

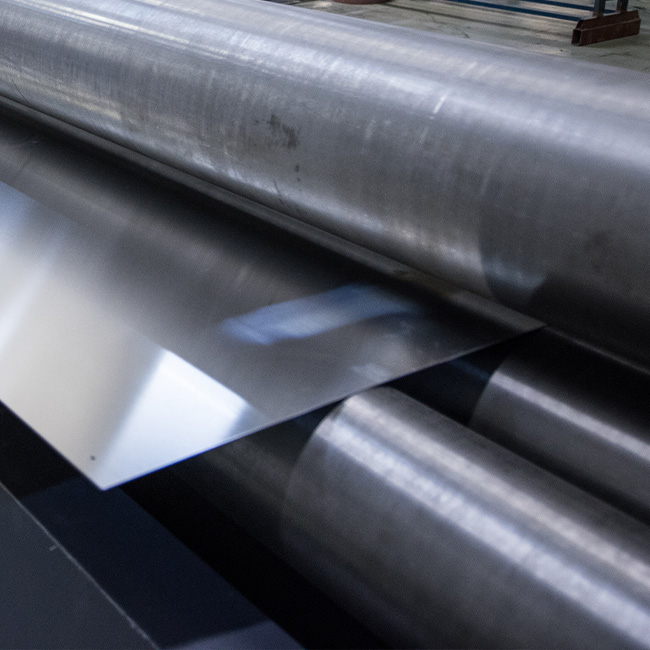

Plate Rolling Services

05.

CNC Machining Services

06.

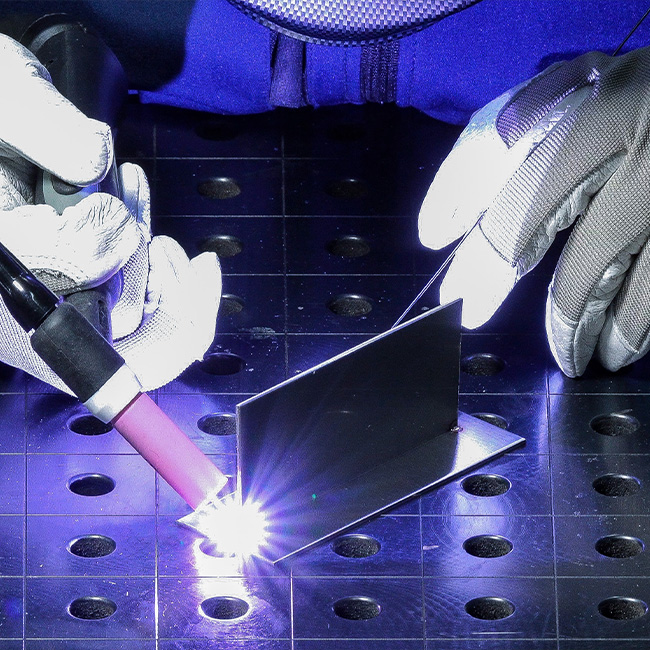

Welding Services

07.

Full Cycle Details Production

08.

Tube Laser Cutting

09.

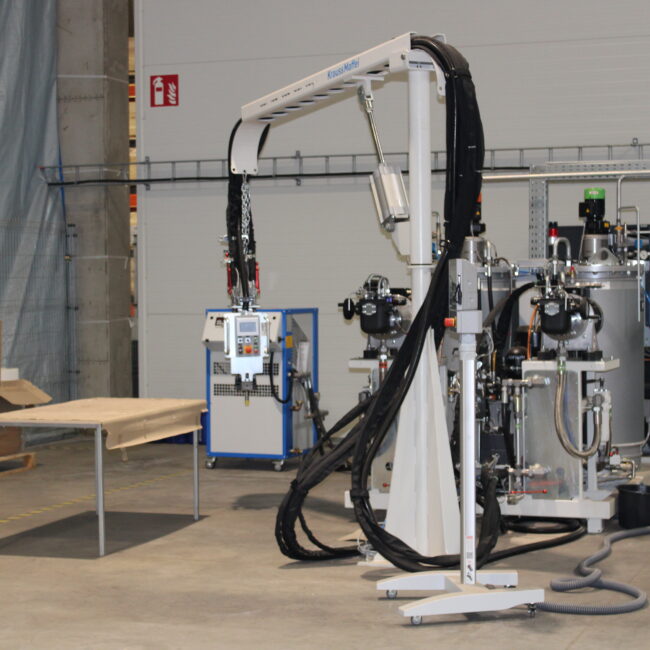

Precision Polyurethane Foam Solutions

10.

CNC Cylindrical Grinding Services

11.

Cable Stretching & Testing Services

Our Equipment

PILOUS ARG380 PLUS S.A.F

Band saw for metal – hydraulic semi-automatic.

- Saw blade speed: 15-90 m/min

- Working height of vice: 810 mm

| round | square | rectangle | |

| 90° | 380 | 340 | 510 x 340 |

| -45° | 380 | 340 | 350 x 340 |

| +45° | 380 | 340 | 350 x 340 |

| +/- 60° | 270 | 255 | 235 x 340 |

PILOUS ARG 520 DC CF-NC

Band saw for metal – dual-column CNC automatic.

- Feed rate of material: 1,6 / 2,5 / 3 m/min

- Saw blade speed: 15-90 m/min

| round | square | rectangle | |

| 90° | 520 | 500 | 700 x 480 |

Bodor T Series Performance Tube Laser Cutting Machine

Tube laser cutting.

| Requirements for Tubes | Diameter < 50 mm, Thickness ≥ 1.2 mm Diameter ≥ 50 mm, Ratio of tube thickness and diameter ≥ 2.5 % |

| Tube Size Range | Diameter: 8-230 mm |

| Maximum Tube Length | 6500 mm / 9200 mm |

| Maximum Tube Weight | 300 kg |

| Max. Chuck Rotating Speed | 160 r/min |

| Max. Chuck Feeding Speed | 160 m/min |

| Shortest Remnant | 90 mm |

| Max. Unloading Length | 4500 mm |

| 1-second centering | + |

| Automatic Adjustment of Clamping force | + |

| Following servo unloading plate | + |

| Intelligent Adaptive Processing | + |

| Combined Roller | + |

HILALSAN AGM 3010 - Hyper

CNC variable rake hydraulic guillotine shear

| Cutting Length | 3080 mm |

| Cutting Capacity, MS | 10 (450 N/mm²) |

| Cutting Capacity, SS | 7,5 (700 N/mm²) |

| Min/max. stroke per minute | 10_19 (stroke/minute) |

| Min. cutting angle | 0,3 |

| Max. cutting angle | 2 |

| Number of downforces | 16 pcs. |

| Min. downforce | 5 tons |

| Max. downforce | 20 tons |

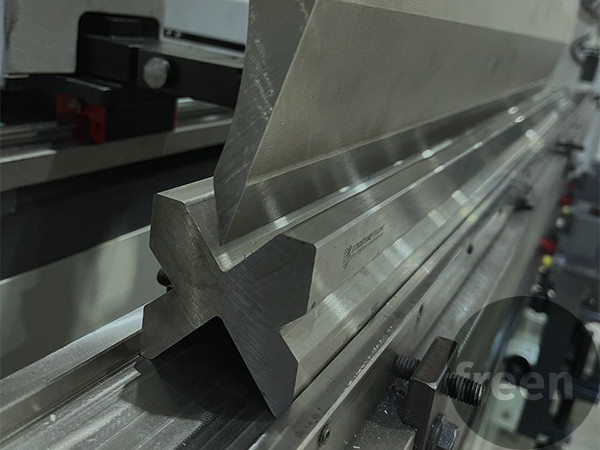

HILALSAN CAP 3135 - Ultimate

Hydraulic CNC press brakes

| Bending force | 135 tons |

| Bending length | 3100 mm |

| Column distance | 2600 mm |

| Stroke | 265 mm |

| Daylight | 485 mm |

| Throat depth | 410 mm |

| Y-axis stroke | 200 mm |

Salvagnini L3-30 with CPE pallet changer

Adaptive CNC fiber laser

Laser power: 2000 W

Working range:

| Worktable size | 3048×1524 |

| Z-axis stroke | 100 mm |

| Position accuracy | 0.08 Pa |

| Average position range | 0.03 Ps |

Cutting capacity (thicknesses):

| Steel (S185JR,S235JR, RAEX 250 C LASER) | 0.5-15 |

| Stainless steel (AISI 304, X5CrNi18-10 1.4301) | 0.5-10 |

| Aluminum (Al 99.5 EN AW 1050A) | 0.5-8 |

| Copper (Cu-ETP CW004A H040 EN1652) | 0.5-5 |

| Brass (CuZn37 CW508L H055 EN1652) | 0.5-5 |

FACCIN 4HEL-1026

4-roll CNC double pinch plate bending machine with linear guides.

| S235 | 260N/mm² | Ø | mm |

| Bending thickness (1000mm) | Ø1325 | 19 | |

| Prebending thickness (1000mm) | Ø1325 | 15 | |

| Bending thickness (1000mm) | Ø340 | 14 | |

| Prebending thickness (1000mm) | Ø340 | 13 | |

| Bending thickness (500mm) | Ø1325 | 23 | |

| Prebending thickness (500mm) | Ø1325 | 19 | |

| S355 | 360N/mm² | Ø | mm |

| Bending thickness (1000mm) | Ø1325 | 17 | |

| Prebending thickness (1000mm) | Ø1325 | 13 | |

| Bending thickness (1000mm) | Ø340 | 13 | |

| Prebending thickness (1000mm) | Ø340 | 11 | |

| Bending thickness (500mm) | Ø1325 | 21 | |

| Prebending thickness (500mm) | Ø1325 | 17 | |

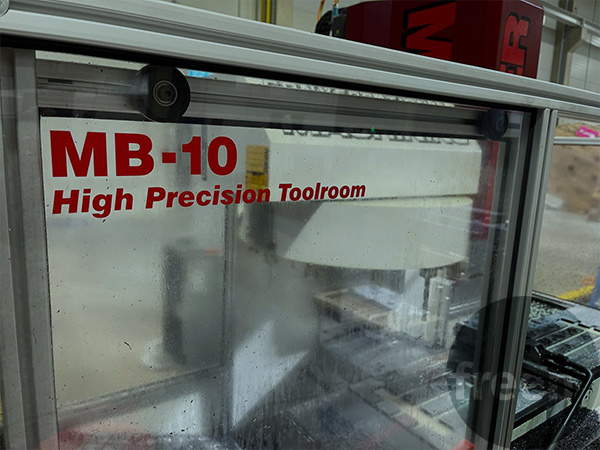

Fryer MB-10R - 2 pcs

CNC Rigid Spindle Head Toolroom Bed Mill

- X-axis stroke: 813 mm

- Y-axis stroke: 432 mm

- Z-axis stroke: 483 mm

- Table load (evenly distributed): 900 kg

- Ballscrew size: 32 mm

- Table size: 356 mm x 1270 mm

- T-slots (No./Width:) 3 / 16 mm

- Spindle: 8 000 RPM

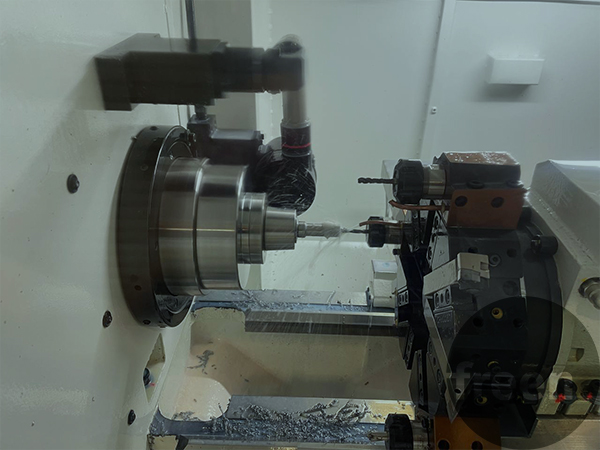

Fryer ET-16 - 2 pcs

Toolroom Turning CNC Lathe

- Bed swing: 406 mm

- Cross slide swing: 206 mm

- Center height: 206 mm

- Center distance: 1016 mm (1524 mm)

- Bed width: 356 mm

- Size of a ballscrew: 41 mm Z – 25 mm X

- Speed of a spindle (RPM): 100 – 3,000

- Quill stroke: 127 mm

- Quill diameter: 63.5 mm

- Quill taper hole: MT-5

Fryer ET-18 /40" - 2 pcs

Toolroom Turning CNC Lathe

- Bed swing: 457 mm

- Cross slide swing: 232 mm

- Center height: 232 mm

- Center distance: 1016 mm

- Bed width: 356 mm

- Size of a ballscrew: 41 mm Z – 25 mm X

- Speed of a spindle (RPM): 50 – 2,500

- Quill stroke: 127 mm

- Quill diameter: 63.5 mm

- Quill taper hole: MT-5

Fryer ET-18 /60" - 2 pcs

Advanced Toolroom Turning CNC Lathe

- Bed swing: 457 mm

- Cross slide swing: 232 mm

- Center height: 232 mm

- Center distance: 1524 mm

- Bed width: 356 mm

- Size of a ballscrew: 41 mm Z – 25 mm X

- Speed of a spindle (RPM): 50 – 2,500

- Quill stroke: 127 mm

- Quill diameter: 63.5 mm

- Quill taper hole: MT-5

Fryer HR-40 - 2 pcs

CNC Fixed Spindle Horizontal Machining Center

- X-axis stroke: 1016 mm

- Y-axis stroke: 737 mm

- Z-axis stroke: 635 mm

- Table load (evenly distributed): 2 720 kg

- Table size: 610 mm x 1295 mm

- T-Slots (No./Width): 5 / 18 mm

- Spindle: 60 – 8 000 RPM

- Size of a platter: 610 mm

- Positioning accuracy: 12 arc seconds

- Positioning repeatability: 5 arc seconds

- Spindle center to table top: 25 mm – 762 mm

Fryer VT-60

Compact, large swing CNC vertical turret lathe

- Max. swing diameter: 1524 mm

- Cutting diameter range: 0 mm – 1524 mm

- Max. cutting length: 813 mm (1219 mm)

- Bed width: 813 mm

- Column stroke (X-axis): 864 mm

- Turret face to spindle center (X-axis): -102 mm – 762 mm

- Longitudinal stroke (Z-axis): 813 mm

- Turret face (bottom) to spindle nose max/min (Z-axis): 203 mm – 1016 mm

- Turret positions: 8

- Size of turret tooling: BMT-65

- Size of a ballscrew: 51 mm X, Z

- Nose of a spindle: A2-15

- Bore of a spindle: 2.625

Fryer VT-80

Compact, large swing CNC vertical turret lathe

- Max. swing diameter: 2032 mm

- Cutting diameter range: 102 mm – 2032 mm

- Max. cutting length: 813 mm (1219 mm)

- Bed width: 813 mm

- Column stroke (X-axis): 965 mm

- Turret face to spindle center (X-axis): 305 mm – 1016 mm

- Longitudinal stroke (Z-axis): 1219 mm

- Turret face (bottom) to spindle nose max/min (Z-axis): 203 mm – 1422

- Turret positions: 12

- Size of turret tooling: BMT-65

- Size of a ballscrew: 51 mm X, Z

- Nose of a spindle: A2-15

- Bore of a spindle: 2.625

CABE SC32-450

Keyseating machine.

The SC32 can produce straight grooves, taper keyways, and grooves in blind holes. It produces regular and multiple keyways and standard and custom internal gears.

- Max. key width: 32 mm

- Max. key length: 450 mm

- Max. cutting speed: 15 m/min

- Max. return speed: 20 m/min

- Cutting force: 40 kN

- Feed: 0.01 – 1.5 mm

- Table size: 640×640

MVD LASER FB 6020 8 kW

Sheet Metal Cutting Machine (fiber laser).

- X-axis stroke: 6030

- Y-axis stroke: 2030

- Z-axis stroke: 120

- Velocity: 2.5

- Positioning accuracy: +/- 0.05

- Repeatability: +/- 0.03

- Max. loading capacity: 4000

- Mild steel: 30

- Stainless steel: 20

- Aluminum: 18

BIT B30-3

PBA-800 CNC aluminum profile bending machine.

- Roller speed: 1-15 rpm

- Max. mold diameter: 360 mm

- Roller diameter: 80 mm

- Fixed shaft center distance: 400~600 mm adjustable

- Y-axis push rod thrust: 30 tons (40 tons max)

- Repeated positioning accuracy of Y-axis push rod: ≤0.02 mm

- Max. X-axis torque: 6000 N.m

- Min. processing radius: 150 mm

- Max. width: 200 mm

- Max. axial height: 250 mm

Studer Favorit CNC

CNC universal cylindrical grinding machine.

favoritCNC is a CNC universal cylindrical grinding machine for the individual and batch production of medium-sized workpieces. Its center distance is 650 / 1000 mm, and its center height is 175 mm. It produces workpieces with a maximum weight of 80 / 120 kg.

Cross slide: X-axis

- Max. travel: 285 mm (11.2″)

- Speed: 0.001 – 10 000 mm / min (0.000.04 – 394 ipm)

- Rotative encoder: 0.0001 mm (0.000.004″)

Longitudinal slide: Z-axis

- Max. travel: 800 / 1 150 mm (31.5″ / 45.3″)

- Speed: 0.001 – 20 000 mm / min (0.000.04–787 ipm)

- Rotative encoder: 0.0001 mm (0.000.004″)

- Machine table: swiveling range 8.5 deg

Wheelhead

- Swiveling range: -15 to +195 deg

- Swiveled manually 2.5 deg Hirth

- Fitting taper dia. 63 mm (2.48″)

Tailstock

- Fitting taper: MT4

- Barrel stroke: 35 mm (1.37″)

- Diameter of a barrel: 50 mm (1.97″)

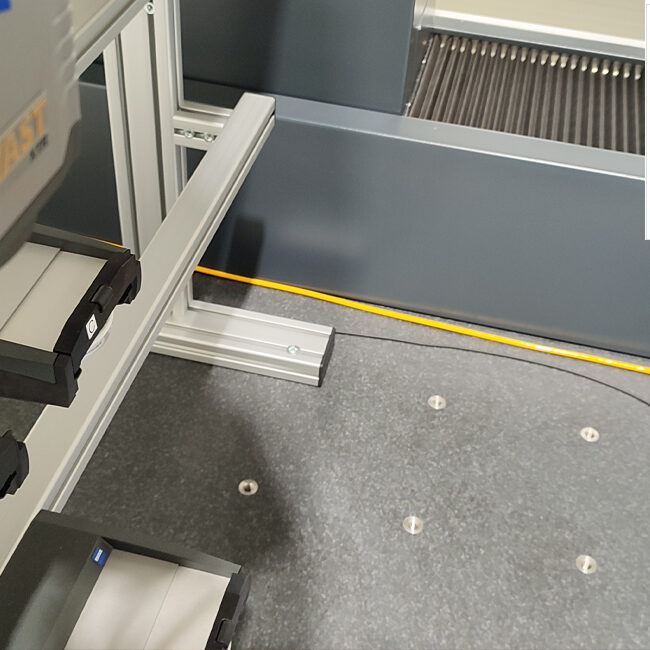

3D coordinate measuring machine CONTURA 9/12/8

New machine for high precision measurements in quality control. ZEISS CONTURA stands for absolute

versatility and fl exibility. The new generation

is equipped with the ZEISS

multi application sensor system (mass)

technology, which makes it possible to

exchange diff erent sensor technologies

quickly and easily.

Measuring range:

| Measuring range, mm (X,Y,Z) | 900x1200x800 |

| Overall CMM dimensions, mm (L,W,H) | 2247x1867x3410 |

| Working range (Max. workpiece size), mm (L,W,H) | 1600x1227x850 |

| Max. workpiece weight, kg | 1200 |

KraussMaffei RimStar Smart 16/16

High-performance polyurethane metering and mixing machine, ideal for producing PU foam components with consistent quality and efficiency. Ensures flexibility in industrial applications where precise mixing and controlled processing are a must.

Capabilities

- Mixing head capacity: 16 L

- Output rate: up to 16 kg/min

- High-pressure metering: up to 250 bar

- Temperature control accuracy: ±1 °C

- Density range: 20–300 kg/m³

SAHM 200 kN Test Bed

High-capacity cable stretching, pre-stretching, and tensile testing machine for industrial wire ropes, cables, and terminal fittings. Designed for precision proof and destructive testing in compliance with EN ISO 7500-1:2018 Class 1 standards.

Capabilities

- Load capacity: 200 kN (20 tons)

- Modular testing length: 11 m

- Hydraulic speed control: 280 mm/min (testing), 1100 mm/min (setup)

- Suitable for pre-stretching, proof testing, and destructive testing

- Custom adapters for terminals and rope fixtures

- Conforms to DIN ISO 2307 and EN 12385 for steel wire rope testing

Our Advantages

Design and Technology Expertise

Our design and technology teams will help you develop and implement your creative ideas by providing cost-effective solutions to any task, whether it be the production of individual components or ready-to-sell products. We use SolidWorks, SolidСAM which allows us to achieve desired results with less effort in a shorter time.

Unparalleled Quality

Quality is our second name! We use only reliable measuring tools that have passed verification. For complex measurements that are difficult to perform with hand tools, we have a measuring machine. We regularly upgrade our machine park, which allows us to provide new types of services within faster production times. Effective manufacturing process allows us to deliver high volume orders.

Comprehensive Approach

We take care of the packaging and delivery of containers, including the groupage of full cargo to practically any region. Average shipping time in EU - 2 working days, in UK - 6 working days. When working with every project (by designing and/or manufacturing it), we strive to provide the highest quality possible and peerless customer service. At your request, we can also perform the assembly procedures.

Our Clients

- 1

- 2

- 3

- 4

- 5

- 6

- 7

Contact Us

subcontractor services request for proposal

Affiliate Program

We invite partners to earn revenue through our metal machine processing affiliate program. Whether you have a potential client for our services or you would like to sale our services for commission - please contact us for program details.